UPDATE:

Results with "Constant Pressure Pliers Handles"

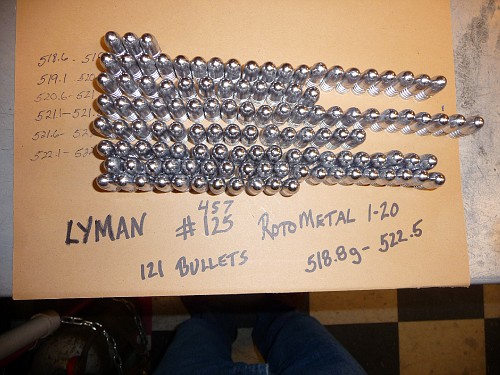

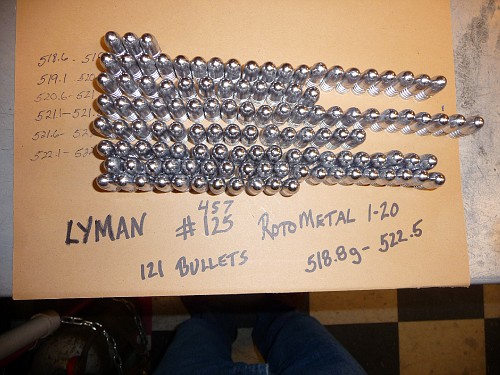

I finally had a few moments to analyze the results of using the constant pressure handles I built;

As you can see. Huge improvement. 3.7g variation. I'm still not sure how you folks are getting 1/2 grain variations. I have a long way to go to get there. But this is huge for my stage in the game.

Here's a quick video of how the pliers are connected to the temperature probe.

BTW, I found my best bullets were cast with the "1-20" Allot at 750 degrees and the Lyman mold at 425 degrees..........

http://public.fotki.com/Rbertalotto/gun ... 20782.html

A few notes on the pliers......

At 425 degree mold temperature, handles got to 91 degrees. No issue even with thin welding gloves.

The tension set screw on the pliers will need a set screw installed or a jam nut to stop it from loosening during use. When the handles are opened to drop a boolit and the pliers are tapped with a wood mallet, the screw is no longer under tension and will loosen after a few taps.

I had to modify the jaws on my pliers. I ground them so only the area around the bolt that holds the pliers to the mold was touching. Before I made this modification the tips of the jaws were holding the top of the mold tightly, but the bottom of the mold showed daylight. I'll do a quick sketch and post.

The handles act as a very good heat-sink on the mold. It was hard to keep the Lyman single cavity mold at 425 degrees. If I slowed down my cadence the mold would go to 400 degrees within 20 seconds. (I did have a fan running to keep me cool and I'm sure it was drawing heat away from the pliers)

It's extremely convenient to be able to "lock" the pliers and then go about pouring and sprew removal without worrying about applying constant pressure.

BTW, "Frosty Bullets are MUCH lighter than shiny bullets. To the order of 10g-15g with this lead and this mold............Thought you'd like to know

All in all, very pleased with the results.