steel

Forum rules

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

steel

2ndovc's post about the anvil & awp101's response got me to thinking.

One of the guys just replaced the leaf springs on his old GMC service truck.

I snagged the springs that came off, good straight springs, no curve.

Good knife stock.

Bet I get an e-mail from AWP101.

One of the guys just replaced the leaf springs on his old GMC service truck.

I snagged the springs that came off, good straight springs, no curve.

Good knife stock.

Bet I get an e-mail from AWP101.

- Old Savage

- Posting leader...

- Posts: 16739

- Joined: Mon Sep 03, 2007 3:43 pm

- Location: Southern California

Re: steel

I have read about knife makers using them for knives.

Re: steel

Ya Mon,

Works really well.

Works really well.

-

CEMENTHEAD

- Levergunner 3.0

- Posts: 918

- Joined: Thu Sep 27, 2007 5:09 pm

- Location: RHODE ISLAND

Re: steel

Good snag.

I buy old files at yard sales and flea markets for the same reason.

Thanks, Tom

I buy old files at yard sales and flea markets for the same reason.

Thanks, Tom

War sees no color, sex, or ethnic background - wars only see blood shed by our heroes for our freedoms.

I Am An American! Fighting for our Country and our way of life.

Fourth Generation Veteran and Proud !!

I Am An American! Fighting for our Country and our way of life.

Fourth Generation Veteran and Proud !!

- fordwannabe

- Advanced Levergunner

- Posts: 3370

- Joined: Thu Apr 02, 2009 8:52 am

- Location: Womelsdorf PA

Re: steel

I made a large bowie from a ford truck spring in 1995ish. Worked pretty well but boy I never thought I'd get that ground. Tom

a Pennsylvanian who has been accused of clinging to my religion and my guns......Good assessment skills.

Re: steel

I aint as fast as I once was, but I cheat real good.

Seriously, I have a surface grinder & a variable angle magnetic vise.

Seriously, I have a surface grinder & a variable angle magnetic vise.

- fordwannabe

- Advanced Levergunner

- Posts: 3370

- Joined: Thu Apr 02, 2009 8:52 am

- Location: Womelsdorf PA

Re: steel

I had a belt sander,and angle grinder(ITHINK) and a couple of files,some sand paper and a sore pair of arms! Tom

a Pennsylvanian who has been accused of clinging to my religion and my guns......Good assessment skills.

-

Gobblerforge

- Senior Levergunner

- Posts: 1504

- Joined: Tue Sep 04, 2007 1:02 pm

- Location: Eastern Ohio, Foothills of Appalachia

- Contact:

Re: steel

After you get the spring cut to length, do yourself a favor and anneal it. This will make it softer and workable. After it is done, then you can re harden it. To anneal it, heat it up in what ever manner you chose to a medium orange and then bury it in some wood ashes over night. Done. To find orange, heat it until the red is gone. It sounds funny but there is a point that is detectable when the red is gone. Now at this orange heat the metal can be slowly cooled to anneal it or quench it for hardening. After hardening, then tempered.

Man, I dig being a Blacksmith.

Gobbler

Man, I dig being a Blacksmith.

Gobbler

Click Click Boom

Re: steel

Not as much as I dig the advice!

Can I e-mail you if I get hung up?

Can I e-mail you if I get hung up?

-

JerryB

- Advanced Levergunner

- Posts: 5493

- Joined: Mon Apr 02, 2007 9:23 pm

- Location: Batesville,Arkansas

Re: steel

You can make some nice tomahawk heads from those springs too. Just weld a piece of pipe to the top for a handle for an eye. The one in the picture is over 40 years old, after several handle replacements.

http://s266.photobucket.com/albums/ii27 ... g&newest=1

http://s266.photobucket.com/albums/ii27 ... g&newest=1

JerryB II Corinthians 3:17, Now the Lord is that Spirit: and where the Spirit of the Lord is, there is liberty.

JOSHUA 24:15

JOSHUA 24:15

Re: steel

Good auto springs were made of 1095 carbon steel. They claim the best comes from auto's made prior to 1939 or there abouts. In WWII they found adding a trace amount of the elemental metal Boron to the smelting process doubled the strength of the steel, but it did affect how it has to be be heat treated. There are a number of people who making smaller blades will use the old coil springs, heat, softened and straightened to make their knives. A good tomahawk can be made out of a piece of round bar stock about 1 and 1/4 inch diameter. Flatten where you want the handel, punch through the stock, then shape and thin the blade and butt of the blade. With a good forge and right fire it isn't bad, helps to have big hammers and punches. FWIW

- AJMD429

- Posting leader...

- Posts: 32212

- Joined: Sun Sep 09, 2007 10:03 am

- Location: Hoosierland

- Contact:

Re: steel

How "no curve" if they're leaf springs...?mescalero2 wrote:2ndovc's post about the anvil & awp101's response got me to thinking.

One of the guys just replaced the leaf springs on his old GMC service truck.

I snagged the springs that came off, good straight springs, no curve.

I always wanted to use a pair of huge leaf springs to make a stationary or vehicle-mounted cross-bow, maybe to shoot metal T-posts at about 800 fps. . .

Doctors for Sensible Gun Laws

"first do no harm" - gun control LAWS lead to far more deaths than 'easy access' ever could.

Want REAL change? . . . . . "Boortz/Nugent in 2012 . . . ! "

"first do no harm" - gun control LAWS lead to far more deaths than 'easy access' ever could.

Want REAL change? . . . . . "Boortz/Nugent in 2012 . . . ! "

- KirkD

- Desktop Artiste

- Posts: 4406

- Joined: Sat Apr 07, 2007 6:52 am

- Location: Central Ontario, Canada

- Contact:

Re: steel

I acquired this sword from a former levergun member that went by the name of 45Stomp. The blade is made from a truck spring. He put a lot of time into it and built it to be a 'working' sword, but it is also a work of art. I am very pleased to own it.

Kirk: An old geezer who loves the smell of freshly turned earth, old cedar rail fences, wood smoke, a crackling fireplace on a snowy evening, pristine wilderness lakes, the scent of

cedars and a magnificent Whitetail buck framed in the semi-buckhorn sights of a 120-year old Winchester.

Blog: https://www.kirkdurston.com/

cedars and a magnificent Whitetail buck framed in the semi-buckhorn sights of a 120-year old Winchester.

Blog: https://www.kirkdurston.com/

Re: steel

Some of them are "Flat "

- kimwcook

- Advanced Levergunner

- Posts: 7978

- Joined: Tue Sep 04, 2007 10:01 pm

- Location: Soap Lake, WA., U.S.A.

Re: steel

As Gobbler said, anneal the piece you want to work. You'll find it a lot easier to work with. The problem with any unknown steel is just that, you don't know what you have. That means you don't know what the temper should be. After annealing, grind away everything that doesn't look like a knife blade to you. You'll have to decide on whether to make a hidden tang, full tang, etc.. When everythings fitted, guard handle, etc.. and the piece ready to be put together. Take the blade up to non-magnetic (heat the steel until a magnet won't stick to it anymore) and edge quench about a third of the width of the blade in warmed Dexron/ATF. Careful, the oil's going to flame up a bit. After the oil quits sizzling and boiling on the blade just drop it in the oil. Take it out when you can stand the heat with your fingers. Now, here's where the temper comes into play. The quenched 1/3 blade is hard and brittle and needs to be tempered back so your blade doesn't chip, break and can be sharpened. You need to find an oven and Mesci since you don't have a lady of the house you can use the house oven. I'd take some aluminum foil and bunch it up so when I placed the spine/back of the blade in the foil it holds the blade standing up. Put the foil on a cookie sheet or the foil can span the grill. Preheat the oven up to 350F and once you heat pre-heat, put the blade in the oven for an hour. When the hours up, pull out the blade and let it cool to room temp. Now get a piece of brass rod, put in in an press and edge test your blade by pushing the edge, at an angle, onto the rod. When you've tempered your piece back far enough the very edge will bend ever so slightly. If it doesn't bend or it chips you know you're too hard and you need to either do a series of tempers at 350 or go 50F higher and go through the temper process again. Rod test it until you're able to get the small bend. Now the bend shouldn't stay in the edge. It should just deflect. Now your blade edge has to be almost at it's end thickness for this test to work. Be careful, sharp things have a way of cutting you when your playing with them. I haven't made a knife yet that hasn't made me bleed one way or another.

Old Law Dawg

-

awp101

- Advanced Levergunner

- Posts: 5670

- Joined: Mon Apr 09, 2007 7:13 pm

- Location: DeeDee Snavely's Used Guns and Weapons

Re: steel

Nope! Too many other irons in the fire!mescalero2 wrote:Bet I get an e-mail from AWP101.

Thanks for the thought though...

Nothing so needs reforming as other people's habits.

-Mark Twain

Proverbs 3:5; Philippians 4:13

Got to have a Jones for this

Jones for that

This running with the Joneses boy

Just ain't where it's at

-Mark Twain

Proverbs 3:5; Philippians 4:13

Got to have a Jones for this

Jones for that

This running with the Joneses boy

Just ain't where it's at

-

Ben_Rumson

- Advanced Levergunner

- Posts: 2569

- Joined: Sat Sep 15, 2007 12:51 pm

Re: steel

I forge worked pieces of truck springs ... A torch will work for annealing too..Mine were thick and had to be drawn out and down to quarter inch ... When it's annealed, it can be draw filed easy... I put a bag of lime in an old BBQ to use to let things cool down slow to anneal...

My finest bit of spring work was when I made one of those little curly kew springs that close the slide on a cap and ball powder flask... DYK a putty knife blade makes up into a fine spring? Stay away from the chromed ones... I annealed it... sawed a strip out of it.. filed it so it had a little leg near one end to go in the retaining hole in the flask head.. then bent it around something handy to get the curve.. heated her up to cherry and slid it off into a cup of motor oil... Cleaned the scale off.. polished it up to bright... Played a torch over it till she ran up to light blue starting towards dark blue... Hooo Weee Nothin' like the drama of bending an intricate hand made spring for the first few times...Will it crack or stay bent out of shape or be a spring??!!! I coulda bought one from DGW for three bucks, but where’s the fun in that!

My finest bit of spring work was when I made one of those little curly kew springs that close the slide on a cap and ball powder flask... DYK a putty knife blade makes up into a fine spring? Stay away from the chromed ones... I annealed it... sawed a strip out of it.. filed it so it had a little leg near one end to go in the retaining hole in the flask head.. then bent it around something handy to get the curve.. heated her up to cherry and slid it off into a cup of motor oil... Cleaned the scale off.. polished it up to bright... Played a torch over it till she ran up to light blue starting towards dark blue... Hooo Weee Nothin' like the drama of bending an intricate hand made spring for the first few times...Will it crack or stay bent out of shape or be a spring??!!! I coulda bought one from DGW for three bucks, but where’s the fun in that!

"IT IS MY OPINION, AND I AM CORRECT SO DON'T ARGUE, THE 99 SAVAGE IS THE FINEST RIFLE EVER MADE IN AMERICA."

WIL TERRY

WIL TERRY

Re: steel

Kim,

I had NO idea you were so multi-talented!

Thank You.

Ben,

You guys are awsome.

I had NO idea you were so multi-talented!

Thank You.

Ben,

You guys are awsome.

- Old Ironsights

- Posting leader...

- Posts: 15084

- Joined: Mon Apr 02, 2007 9:27 am

- Location: Waiting for the Collapse

- Contact:

Re: steel

That's a GREAT sword (no wait, it's a bastard sword...) Kirk!

I've seen some mighty nice Gladii and Spathas (among other short swords) too, but that one looks like a peach to swing.

I've seen some mighty nice Gladii and Spathas (among other short swords) too, but that one looks like a peach to swing.

C2N14... because life is not energetic enough.

מנא, מנא, תקל, ופרסין Daniel 5:25-28... Got 7.62?

Not Depressed enough yet? Go read National Geographic, July 1976

Gott und Gewehr mit uns!

מנא, מנא, תקל, ופרסין Daniel 5:25-28... Got 7.62?

Not Depressed enough yet? Go read National Geographic, July 1976

Gott und Gewehr mit uns!

-

Gobblerforge

- Senior Levergunner

- Posts: 1504

- Joined: Tue Sep 04, 2007 1:02 pm

- Location: Eastern Ohio, Foothills of Appalachia

- Contact:

Re: steel

Mescalero. Just keep posting here instead of e-mail. That way everyone can read, learn or give input.

Kim. I like to use the oven to temper also but I think 350 is a little too low. I go to about 425-450. I also prefer to harden the whole blade and temper the whole blade as well.

Gobbler

Kim. I like to use the oven to temper also but I think 350 is a little too low. I go to about 425-450. I also prefer to harden the whole blade and temper the whole blade as well.

Gobbler

Click Click Boom

- Ysabel Kid

- Moderator

- Posts: 27900

- Joined: Mon Sep 17, 2007 7:10 pm

- Location: South Carolina, USA

- Contact:

Re: steel

I remember you posting that picture before. Yep - a work of art!KirkD wrote:I acquired this sword from a former levergun member that went by the name of 45Stomp. The blade is made from a truck spring. He put a lot of time into it and built it to be a 'working' sword, but it is also a work of art. I am very pleased to own it.

Looks like you are going to get a work out mescalero!

Re: steel

ok Gobblerforge,

Let's go:

Some many years ago I started a Bowie knife project.

I followed guidelines from The American Bladesmith Society for a Bowie.

Flat ground.

9 1/2'' blade length

tip on centerline of thrust

sharpened clip, for cuts on the backstroke

I used a truck spring, ( that had a curveture )

The place I worked at had a pot used to cast aluminum.

To remove the curve in the steel, I heated to red hot, layed it on the concrete floor, placed a cinderblock on top and let it cool.

I then shaped & ground, then the project lingered.

What do I need to do to restore the structural integrity of the steel at this point?

Let's go:

Some many years ago I started a Bowie knife project.

I followed guidelines from The American Bladesmith Society for a Bowie.

Flat ground.

9 1/2'' blade length

tip on centerline of thrust

sharpened clip, for cuts on the backstroke

I used a truck spring, ( that had a curveture )

The place I worked at had a pot used to cast aluminum.

To remove the curve in the steel, I heated to red hot, layed it on the concrete floor, placed a cinderblock on top and let it cool.

I then shaped & ground, then the project lingered.

What do I need to do to restore the structural integrity of the steel at this point?

Re: steel

I guess I should have asked the question in the last post.

Do I need to anneal first?

Do I need to anneal first?

Re: steel

I would anneal it first. You are not forging to shape then grinding to fit are you? If you are just doing the whole process with a grinder annealing will save you a lot of time and wear on your grinder.

Jeremy

GySgt USMC Ret

To err is human, To forgive is devine, Neither of which is Marine Corps policy

Semper Fidelis

GySgt USMC Ret

To err is human, To forgive is devine, Neither of which is Marine Corps policy

Semper Fidelis

Re: steel

All the work has been done, it is at final configuration.

Re: steel

It is probably worth mentioning, but to see the colors in the steel when heating, it is best done in some type of shade and not in the sunlight. Bright sunlight makes it more difficult to tell the color change. Some folks use a magnet to test for temperature as when carbon steel gets hot enough to be worked it loses its magnetic properties. The different types of steel really do have different working properties and it is best to know which you are working on. For the hobbyist, it is a lot of fun.

D. Brian Casady

Quid Llatine Dictum Sit, Altum Viditur.

Advanced is being able to do the basics while your leg is on fire---Bill Jeans

Don't ever take a fence down until you know why it was put up---Robert Frost

Quid Llatine Dictum Sit, Altum Viditur.

Advanced is being able to do the basics while your leg is on fire---Bill Jeans

Don't ever take a fence down until you know why it was put up---Robert Frost

- kimwcook

- Advanced Levergunner

- Posts: 7978

- Joined: Tue Sep 04, 2007 10:01 pm

- Location: Soap Lake, WA., U.S.A.

Re: steel

Gobbler, I'd rather start a little low on the temper and have to go back and try again as compared to tempering at too high a temp and going too soft in one shot as Mesci doesn't know what type of steel he has. I agree he'll probably end up going higher, but he won't have to start all over. Edge quenching as compared to a complete dip would require a whole thread in itself. Small blades are okay. Large blades I prefer the edge quench. Personal opinion don't ya know.

Old Law Dawg

Re: steel

I DO know the steel, I have it written down in my keep for future ref. file.

It is a common GM propriatary spring steel.

It is a common GM propriatary spring steel.

- kimwcook

- Advanced Levergunner

- Posts: 7978

- Joined: Tue Sep 04, 2007 10:01 pm

- Location: Soap Lake, WA., U.S.A.

Re: steel

I don't know how far that'll get ya unless another smith has worked with it and knows it's characteristics. I think if you treat it like 5160 you'd be okay. Good luck, brother. Keep us informed. Oh, pictures are mandatory. We need to see your progress.mescalero2 wrote:I DO know the steel, I have it written down in my keep for future ref. file.

It is a common GM propriatary spring steel.

Old Law Dawg

Re: steel

Thanks Cus,

Nothing like a little pressure.

Nothing like a little pressure.

-

Gobblerforge

- Senior Levergunner

- Posts: 1504

- Joined: Tue Sep 04, 2007 1:02 pm

- Location: Eastern Ohio, Foothills of Appalachia

- Contact:

Re: steel

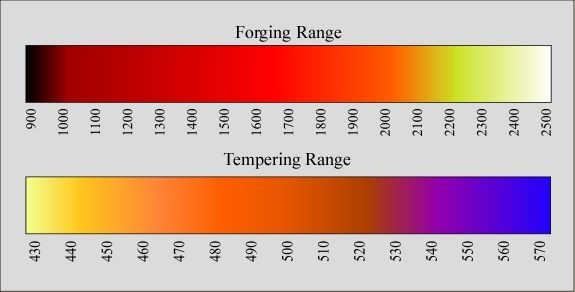

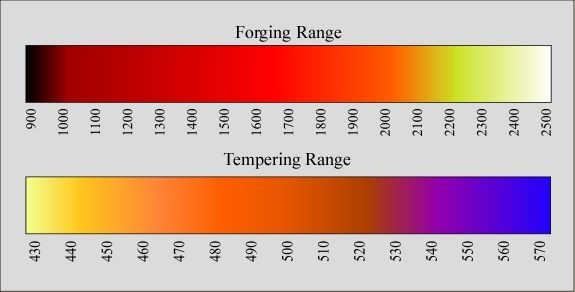

All right, here's what I do. Now that the shaping and grinding is all done, the blade can be hardened. Bring the entire blade and tang to orange heat. From this heat I plunge it fully into a 5 gallon bucket of used motor oil with other oils in it as well. The type of oil is not as important to me as the temperature. You want it room temp. I do this with the knife horizontal and the edge up and pointing towards the north pole. this way the knife back hits the oil first and is easier in the edge which gets to the oil a nano later. The north south direction, I read a few reports about this being the best to keep the magnetic flow of the earth in line with the blade and reducing the chance of the blade warping as it cools. This maybe hocus pocus but I've never had a blade warp and I ain't here to tick off any Gods. If it works, it works. Now, as you thrust the knife into the oil as described, keep the knife going up and down in the bucket. This keeps the air bubbles that occur from staying on the steel and insulating it from a proper quench. Now pull the knife out after a minute or so and it should be cool enough to touch. Now it it hard but brittle so no banging on it yet. There will be a black coating on the steel from the oil that can be brushed and sanded off. Once the steel is clean of oxidation it can be tempered. This is done by putting it in the oven at some 425 to 450 for an hour or two. This step keeps the hardness but takes out the stresses and the steel will be tough, not brittle. Now you are ready to finish sanding and what ever. The temper colors are very exact and when you bring the blade out of the oven it will have a bronze color to it. The color will change with the temperature of the steel to the tune of every 25 to 50 degrees giving different colors. If you go all the way up towards the blue, you are almost back to normalizing and taking the hardness back out, and this is only by 600 degrees. If this happens, it is not a disaster. You just have to start over with the hardening again. another way to temper a knife is to heat a block of iron and set the back of the knife on it to start to absorb the heat. It will migrate from the back to the edge and will give you a rainbow effect. When the color you want is almost to the edge, you have to quench to stop the process. This is a little tough to do for beginners so I recommend the oven method. The plus side to tempering by eye is the back of the blade will be tougher because it gets softer while the edge will be harder and hold the edge well.

Here is a visual. I made this hardie for my anvil a couple years ago. I took the photo for a demo and fortunately kept the photo. It shows the tempering colors pretty well. After hardening I started to heat the bottom part, the part in the anvil, and as the colors migrated towards the edge, I quenched it as the bronze color was just at the edge. You can see the blue down from the edge a ways. This hardy is soft at the bottom, hard at the top but no line between. The transition from hard to soft is spread out and makes the tool very strong.

The temper and heating colors.

Gobbler

Here is a visual. I made this hardie for my anvil a couple years ago. I took the photo for a demo and fortunately kept the photo. It shows the tempering colors pretty well. After hardening I started to heat the bottom part, the part in the anvil, and as the colors migrated towards the edge, I quenched it as the bronze color was just at the edge. You can see the blue down from the edge a ways. This hardy is soft at the bottom, hard at the top but no line between. The transition from hard to soft is spread out and makes the tool very strong.

The temper and heating colors.

Gobbler

Click Click Boom

Re: steel

Gobblerforge,

Thank you, very informative.

Thank you, very informative.

- kimwcook

- Advanced Levergunner

- Posts: 7978

- Joined: Tue Sep 04, 2007 10:01 pm

- Location: Soap Lake, WA., U.S.A.

Re: steel

I'd like to address that there are many ways to skin a cat and I'm not here to contradict anyone especially, Gobbler. Just different strokes.

Another way to check your blade hardness to see if it's where it should be is the file method. Once you've gone through your quench and temper, place the blade in a bise, take a good file and try to file the edge. This is done across the edge and not along it. The file should try and bite, but should also skate. It's this middle ground you're looking for. It's a bit easier than the rod test. When you're blade has reached this point it's hard enough to hold an edge, but soft enough to be sharpened fairly easily and not so prone to chipping.

Another way to check your blade hardness to see if it's where it should be is the file method. Once you've gone through your quench and temper, place the blade in a bise, take a good file and try to file the edge. This is done across the edge and not along it. The file should try and bite, but should also skate. It's this middle ground you're looking for. It's a bit easier than the rod test. When you're blade has reached this point it's hard enough to hold an edge, but soft enough to be sharpened fairly easily and not so prone to chipping.

Old Law Dawg

-

Gobblerforge

- Senior Levergunner

- Posts: 1504

- Joined: Tue Sep 04, 2007 1:02 pm

- Location: Eastern Ohio, Foothills of Appalachia

- Contact:

Re: steel

Kim is correct in the availability of different methods. I use the file test myself for some applications. Another is the spark test but I have never gotten a grip on that one. I've seen so many ways to do the same thing that it is for certain there are more to see. It is said that if you ask 10 smiths how to do something, you'll get 11 answers. The one asking will have another way.

This is merely one of my methods.

JReed brought up a good website for smithing information. IForge has a lot of good folks.

Gobbler

This is merely one of my methods.

JReed brought up a good website for smithing information. IForge has a lot of good folks.

Gobbler

Click Click Boom

- Griff

- Posting leader...

- Posts: 20864

- Joined: Sat Mar 31, 2007 4:56 pm

- Location: OH MY GAWD they installed a STOP light!!!

Re: steel

Another piece of steel that makes great knife material, railroad spikes. I have several... figure that when I retire I'll build my forge then, and work up some knives.

I'm used to workin' with both hot and cold steel from my horsehoein' days... but tempering and hardening are things I've left to professionals. Although I did get proficient at forge welding. Not easy, but once done, it's stuck! Guess I still got a lot to learn... just from readin' Gobblerforge's posts! North-south to appease the forge Gods, huh? Good'un Gobblerforge!!!

North-south to appease the forge Gods, huh? Good'un Gobblerforge!!!

I'm used to workin' with both hot and cold steel from my horsehoein' days... but tempering and hardening are things I've left to professionals. Although I did get proficient at forge welding. Not easy, but once done, it's stuck! Guess I still got a lot to learn... just from readin' Gobblerforge's posts!

Griff,

SASS/CMSA #93

NRA Patron

GUSA #93

There is a fine line between hobby & obsession!

AND... I'm over it!!

No I ain't ready, but let's do it anyway!

SASS/CMSA #93

NRA Patron

GUSA #93

There is a fine line between hobby & obsession!

AND... I'm over it!!

No I ain't ready, but let's do it anyway!